Unyango lobushushu obuphezulu lohlulwe lwaziindidi ezimbini: enye yokucima ubushushu obungaphezulu kunye nobushushu bonyango, kwaye olunye lunyango lobushushu bemichiza.Indlela yokuvavanya ubulukhuni ngolu hlobo lulandelayo:

1. ukucima okungaphezulu kunye nonyango olushushu olushushu

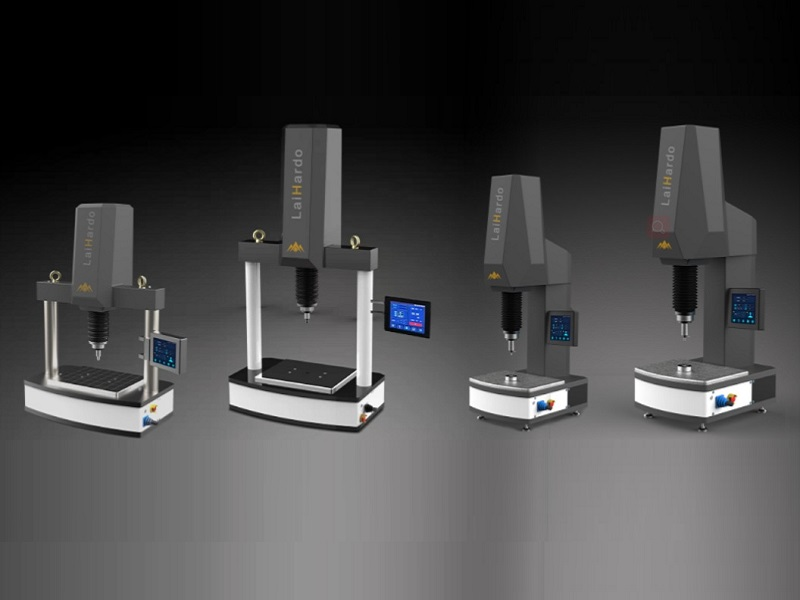

Ukucima okungaphezulu kunye nokushisa unyango oluqhelekileyo luqhutywa ngokufudumeza kwe-induction okanye ukufudumeza ilangatye.Ezona parameters zobugcisa bubulukhuni obungaphaya, ubulukhuni bendawo kunye nobunzulu obusebenzayo bomaleko.Umvavanyi wobulukhuni beVickers okanye iRockwell hardness tester ingasetyenziselwa uvavanyo lokuqina.Amandla okulinga Ukhetho lunxulumene nobunzulu bomaleko oqinileyo osebenzayo kunye nobunzima obungaphezulu bomsebenzi.Kukho oomatshini bokuqina abathathu ababandakanyekayo apha.

1Ingasebenzisa amandla okulinga e-0.5-100KG ukuvavanya umaleko wokuqina ongaphezulu njengobhityile njengo-0.05mm ubukhulu.Ukuchaneka kwayo kuphezulu kwaye iyakwazi ukwahlula i-workpieces ephethwe ukushisa.Umahluko omncinci kubunzima obuphezulu, ukongeza, ubunzulu bomaleko oqinileyo obusebenzayo bufunyenwe ngumvavanyi wobulukhuni beVickers, ngoko ke kuyimfuneko ukuxhobisa umvavanyi wobulukhuni beVickers kwiiyunithi ezenza unyango oluphezulu okanye usebenzise inani elikhulu. yezinto zokusebenza zokunyanga ubushushu obuphezulu.

(2) Umvavanyi wobulukhuni be-Rockwell ongaphezulu ufanelekile kakhulu ukuvavanya ubulukhuni be-workpiece ecinyiweyo.Kukho izikali ezithathu zomvavanyi wobulukhuni beRockwell onokuthi ukhethe kuwo.Inokuvavanya izixhobo zokusebenza eziqinileyo ezingaphezulu kwe-0.1mm.Nangona ukuchaneka kwe-Rockwell hardness tester engekho phezulu kunomvavanyi wobulukhuni beVickers, iyakwazi ukuhlangabezana neemfuno njengendlela yokufumanisa yokulawula umgangatho kunye nokuhlolwa kwesiqinisekiso sezityalo zonyango lobushushu..Ngaphandle koko, ikwanayo neempawu zokusebenza okulula, ukusetyenziswa ngokufanelekileyo, ixabiso eliphantsi, ukulinganisa ngokukhawuleza, kunye nokufunda ngokuthe ngqo amaxabiso obunzima.Umvavanyi wobulukhuni be-Rockwell ongaphezulu unokusetyenziselwa ukukhangela ngokukhawuleza nangokungonakalisi iibhetshi zezixhobo zokusebenza eziphathwe ubushushu obuphezulu nganye nganye.Ibaluleke kakhulu kwiifektri zokwenziwa kwesinyithi kunye nokuvelisa oomatshini.Xa ubushushu obuphezulu bonyango obuqinileyo bungqindilili, umvavanyi wobulukhuni beRockwell nawo unokusetyenziswa.Xa unyango lobushushu ubulukhuni umaleko ubukhulu 0.4-0.8mm, isikali HRA ingasetyenziswa.Xa ubunzulu bomaleko obunzima Xa bungaphezulu kwe-0.8mm, isikali se-HRC sinokusetyenziswa.UVickers, uRockwell kunye nomgangatho ophezulu we-Rockwell amaxabiso asemgangathweni amathathu anokuguqulwa ngokulula komnye nomnye, aguqulelwe kwimigangatho, imizobo okanye amaxabiso obunzima afunwa ngabasebenzisi, kwaye itafile yokuguqulwa ehambelanayo ikwi-ISO yomgangatho wamazwe ngamazwe.Umgangatho we-ASTM waseMelika kunye nomgangatho waseTshayina we-GB/T unikiwe.

(3) Xa ubukhulu bomgangatho owenziwe ngobushushu bungaphezulu kwe-0.2mm, i-Leeb hardness tester ingasetyenziswa, kodwa i-C-type sensor kufuneka ikhethwe.Xa ulinganisa, ingqalelo kufuneka ihlawulwe ekugqityweni okungaphezulu kunye nobukhulu obupheleleyo be-workpiece.Le ndlela yokulinganisa ayinayo i-Vickers kunye ne-Rockwell Umhloli wobulukhuni uchanekile, kodwa ufanelekile umlinganiselo wesayithi kwi-factory.

I-2 yonyango lokushisa kweekhemikhali

Unyango lobushushu beMichiza kukufaka umphezulu we-workpiece kunye neeathom zento enye okanye ezininzi zeekhemikhali, ngaloo ndlela utshintsha ukwakheka kweekhemikhali, ulwakhiwo kunye nokusebenza komphezulu we-workpiece.Emva kokucima kunye nokushisa okuphantsi kweqondo lokushisa, i-superficial ye-workpiece inobunzima obuphezulu kunye nokumelana nokunxiba.kunye namandla okudibana nokudinwa, kwaye undoqo we-workpiece unamandla aphezulu kunye nokuqina.Iiparamitha eziphambili zobugcisa bomsebenzi wokunyanga ukushisa kweekhemikhali bubunzulu bomaleko obunzima kunye nobunzima obungaphezulu.Umgama apho ukuqina kwehla ukuya kwi-50HRC bubunzulu obusebenzayo bomaleko oqinileyo.Uvavanyo lobulukhuni obuphezulu bemichiza yokusebenzela enyangwe bubushushu buyafana novavanyo lobulukhuni bezixhobo zokusebenza ezinyangwa ngubushushu obungaphezulu.Abavavanyi bobulukhuni beVickers, abavavanyi bobulukhuni beRockwell okanye abavavanyi bobulukhuni beRockwell bangasetyenziswa.Umvavanyi wobulukhuni ukubona, kuphela ubukhulu be-nitriding thicker buncinci, ngokubanzi abukho ngaphezu kwe-0.7mm, emva koko umvavanyi wobulukhuni be-Rockwell awunakusetyenziswa.

3. unyango lobushushu bendawo

Ukuba iindawo unyango ubushushu basekuhlaleni zifuna ubulukhuni eliphezulu lendawo, unyango ukucima ubushushu lendawo ukucima kunokwenziwa ngokusebenzisa ukufudumeza induction, njl iindawo ezinjalo ngokuqhelekileyo kufuneka uphawu kwindawo yokucima ubushushu unyango lwendawo kunye nexabiso lendawo ubulukhuni kumzobo, kunye nobulukhuni. uvavanyo lwamacandelo kufuneka luqhutywe kwindawo echongiweyo, isixhobo sokuvavanya ubulukhuni singasebenzisa i-Rockwell hardness tester ukuvavanya ixabiso lobunzima be-HRC.Ukuba unyango lobushushu lukhuni umaleko alinzulwanga, umvavanyi wobulukhuni be-Rockwell ongaphezulu unokusetyenziselwa ukuvavanya ixabiso lobulukhuni be-HRN.

Ixesha lokuposa: Aug-16-2023