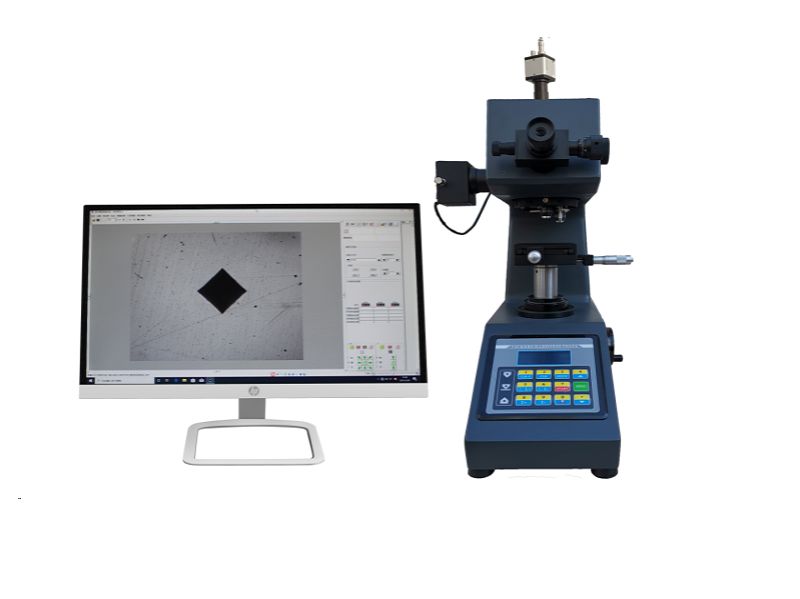

Ubunzima kwindawo ejikeleze i-weld bunokunceda ekuvavanyeni ubulukhuni be-weld, ngaloo ndlela kukuncede uqonde ukuba i-weld inamandla afunekayo na, ngoko ke indlela yokuvavanya ubulukhuni be-weld ye-Vickers yindlela enceda ekuvavanyeni umgangatho we-weld.

Umvavanyi wobulukhuni weShandong Shancai/Laizhou Laihua Testing Instrument Company unokwenza uvavanyo lobulukhuni kwiindawo ezidityanisiweyo okanye kwiindawo zokuwelda. Xa kuvavanywa ubulukhuni bendawo yokuwelda, kuya kwenziwa imilinganiselo yamanqaku amaninzi kumgama othile ukusuka kumphetho wesampulu okanye phezulu kwendawo yokuwelda. Emva kokufumana ukutsalwa kwamanqaku amaninzi, ixabiso lobulukhuni linokulinganiswa ngokulinganisa okuqhubekayo kwaye igrafu yegophe inokufunyanwa.

Xa usebenzisa isixhobo sokuvavanya ubunzima beVickers ukuvavanya iindawo ezidityanisiweyo, kufuneka kuqatshelwe le miqathango ilandelayo yovavanyo:

1. Ukuthamba kwesampuli: Ngaphambi kokuvavanya, siyayigaya i-weld eza kuvavanywa ukuze senze umphezulu wayo ube mpuluswa, ungabi namanqatha e-oxide, imifantu kunye nezinye iziphene.

2. Kumgca osembindini we-weld, thatha inqaku kumphezulu ogobileyo rhoqo emva kwe-100 mm ukuze kuvavanywe.

3. Ukukhetha amandla ovavanyo ahlukeneyo kuya kuphumela kwiziphumo ezahlukeneyo, ngoko ke kufuneka sikhethe amandla ovavanyo afanelekileyo ngaphambi kokuvavanya.

Umvavanyi we-microhardness uneemfuno zokugqitywa komphezulu wesampuli evavanyiweyo, ekufuneka zilungiswe ngononophelo ngokwesampulu ye-metallographic.

Umgaqo wovavanyo lobunzima obuncinci kwindlela yovavanyo lobunzima obuncinci ufana nqwa nobunzima beVickers, kodwa umthwalo osetyenzisiweyo mncinci kunobunzima beVickers obuphantsi, ngokuqhelekileyo bungaphantsi kwe-1000g, kwaye ukutsalwa okuphumayo kungama-microns ambalwa ukuya kuma-microns amabini ambalwa, ngoko ke uvavanyo lobunzima obuncinci lubonelela ngendlela elula kakhulu yokufunda iimpawu zesakhiwo esincinci somaleko onokungena. Isetyenziswa kakhulu ukufumanisa ubunzima besigaba ngasinye kumphezulu nakwimaleko ongena.

Uphawu lwe-microhardness ludla ngokubonakaliswa yi-HV, kwaye umgaqo wayo wokumisela kunye nendlela yayo ifana nendlela ye-Vickers hardness. Inkqubo yokulayisha, inkqubo yokulinganisa kunye nokuchaneka kwe-indenter ye-microhardness tester zifuna kakhulu kunezo ze-Vickers hardness tester ezinomthwalo ophantsi. Okwangoku, i-microhardness tester isetyenziswa kakhulu kwiindawo zokusebenza ezincinci, kwaye ngenxa yokuba ukukhulisa kunokufikelela amaxesha angama-400, idla ngokusetyenziswa njenge-metallographic microscope elula.

Kwinkqubo yokusebenzisa, kufuneka kuqwalaselwe umthwalo, i-micrometer kunye ne-indenter yesivavanyeli sobunzima be-microhardness, ekufuneka zijongwe ngaphambi kokuba zisetyenziswe, kwaye ibhloko yobunzima isetyenziselwa ukuchongwa ngokupheleleyo kwexabiso layo elibonisayo.

Umvavanyi we-microhardness usebenzisa umthwalo kumsebenzi wovavanyo ngokutyibilikayo nangokufanayo kangangoko, ngaphandle kwempembelelo kunye nokungcangcazela. Ukuze kuqinisekiswe ukuchaneka kweziphumo zovavanyo, kudla ngokufuneka ukuba ulinganise amaxesha amaninzi kwiindawo ezahlukeneyo, kwaye ufumane ixabiso eliqhelekileyo elimele ixabiso lobunzima beleyara yovavanyo lokuvuleka okanye isigaba se-alloy. Kwileya yokungena esetyenziswa kubushushu obuphezulu, ubunzima bayo bunokulinganiswa ngokusebenzisa umvavanyi we-microhardness wobushushu obuphezulu.

Ixesha leposi: Epreli-10-2024