Kukho iintlobo ezininzi zeengubo zesinyithi. Iingubo ezahlukeneyo zifuna amandla ovavanyo ahlukeneyo kuvavanyo lwe-microhardness, kwaye amandla ovavanyo awanakusetyenziselwa ngokungacwangciswanga. Endaweni yoko, iimvavanyo kufuneka zenziwe ngokuhambelana namaxabiso amandla ovavanyo acetyiswa yimigangatho. Namhlanje, siza kwazisa ikakhulu uvavanyo lobunzima be-micro Vickers beengubo ze-zinc okanye iingubo ze-zinc-aluminium-magnesium alloy ezisetyenziswa kwintsimbi.

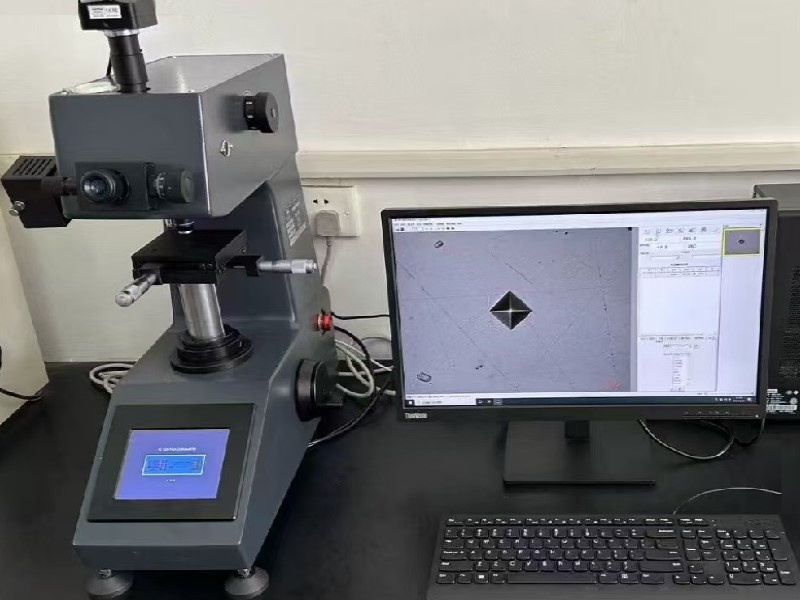

1. Ukulungiselela iisampulu ze-metallographic ezikumgangatho ophezulu zeengubo ze-zinc (okanye iingubo ze-aluminium-magnesium) linyathelo lokuqala lokuvavanya ukugquma. Ukulungiselela iisampulu zokugquma ze-zinc kubandakanya amanyathelo amaninzi, kuquka ukuhluza, ukufaka, kunye nokugawula nokupholisha kwangaphambili. Injongo yokulungiselela ezo sampuli kukugquma umphezulu onqamlezileyo wento yokusebenza ube ngumphezulu ogudileyo, othe tyaba ovumela ukubonakala ngokucacileyo kweengubo ze-Vickers, okwenza kube lula ukulinganisa ngokuchanekileyo ubungakanani bokugquma ukuze kufunyanwe amaxabiso obunzima.

2. Ukuvavanya ubulukhuni beengubo ze-zinc: ekubeni iingubo ze-zinc zixinene, uvavanyo lobulukhuni lunokwenziwa ngamandla ovavanyo ahlukeneyo. Kwisampulu efanayo, okukhona amandla ovavanyo asetyenziswayo emancinci, kokukhona ubungakanani bokugoba buncinci; ngokuchaseneyo, amandla ovavanyo makhulu, kokukhona ubukhulu bokugoba bukhulu. Ukuba ingubo ejikeleze ukugoba ibonisa iimpawu zokuqhekeka okanye zokuguquka, kufuneka kukhethwe amandla ovavanyo amancinci. Le nkqubo iphindaphindwa de ingubo ejikeleze ukugoba kwe-Vickers ihlale ingaguquki kangako ngaphandle kokuguquka—eli nqanaba lamandla ovavanyo lelona lifanelekileyo kwisampulu.

2.1 Ubukhulu obahlukeneyo bokugquma buhambelana noluhlu oluthile lwamandla ovavanyo, nto leyo ibalulekileyo ekuphepheni ukugqwethwa kweziphumo zovavanyo. Oku kulandelayo yireferensi yokukhetha amandla ovavanyo kwiingubo eziqhelekileyo (i-zinc plating, i-chromium plating), esebenza kubavavanyi bobunzima be-micro Vickers (HV):

| Uhlobo lokwaleka | Ukwaleka Ubukhulu (μm) | Cebisa Uvavanyo lwaMandla (gf) | Ehambelanayo Isikali se-HV | Amanyathelo okhuseleko aphambili |

| Izinki Ukusikwa | 5 ~ 15 | 25 ~ 50 | HV0.025, HV0.05 | I-zinc plating ithambile (ngesiqhelo yi-HV50~150); amandla amancinci athintela ukuxinana okugqithisileyo. |

| Izinki Ukusikwa | 15 ~ 50 | 50 ~ 100 | HV0.05, HV0.1 | Njengoko ubukhulu busanda, amandla anokuphakanyiswa ngokufanelekileyo ukuqinisekisa ukuba imiphetho yokutshona icacile. |

| I-Chromium Ukusikwa | 1 ~ 5 | 10 ~ 25 | HV0.01, HV0.025 | I-chromium eqinileyo (HV800~1200) inobunzima obuphezulu; amandla amancinci athintela umonakalo we-indenter. |

| I-Chromium Ukusikwa | 5 ~ 20 | 25 ~ 100 | HV0.025, HV0.1 | Xa ubukhulu >10μm, i-HV0.1force ilinganisa ukuchaneka nokusebenza kakuhle. |

| Isidibanisi Ukwaleka | <5 | ≤25 | HV0.01, HV0.025 | Kwizinto zokugquma ezifana ne-zinc-nickel alloy kunye ne-chromium-nickel alloy, thintela ngokungqongqo ukungena kwento egqumayo. |

2.2 Ezinye Izinto Eziphambili Ezinefuthe

Ukongeza kubukhulu, ezi zinto zimbini zilandelayo ziya kutshintsha ngakumbi ukhetho lwamandla ovavanyo, kwaye kufuneka zigwebe ngokusekelwe kwiimeko zokwenyani:

Uluhlu Lokuqina Kwengubo:

Iingubo ezithambileyo (umz., i-zinc plating, i-HV < 200): Ukuba amandla ovavanyo mancinci kakhulu, ukuxinana kusenokungacaci ngenxa yokuguquka kweplastiki kwengubo. Kucetyiswa ukuba ukhethe umda ophezulu woluhlu olucetyiswayo (njengo., ubukhulu be-10 μm, khetha amandla ovavanyo angama-50gf).

Iingubo eziqinileyo (umz., i-chromium plating, i-HV > 800): Ubulukhuni obuphezulu bubangela ukuxinana okuncinci, ngoko ke amandla ovavanyo akufuneki abe mancinci kakhulu (njengobukhulu obuyi-5 μm, khetha amandla ovavanyo angama-25gf) ukuthintela impazamo yokulinganisa i-diagonal yokuxinana ekudluleni kwe-±5%.

2.3 Iimfuno zeMigangatho kunye neeNkcukacha

Amashishini ahlukeneyo anemigangatho ecacileyo. Umzekelo:

Ishishini leemoto lidla ngokusebenzisa i-ISO 14577 (Uvavanyo lokuNqanda izixhobo), oluvumela ukulungiswa kwexabiso lamandla ngokwesixa sobukhulu bengubo;

Ishishini ngokubanzi libhekisa kwi-ASTM E384, efuna ukuba i-indentation diagonal ibe yi-≤ 1/2 yobukhulu be-coating kunye ne-≥ izihlandlo ezili-10 kune-radius ye-indenter tip (ukuthintela isiphumo se-tip).

Ukuqukumbela, ukukhethwa kwamandla ovavanyo lovavanyo lobunzima be-micro-Vickers kwiingubo zesinyithi kuya kulandela ingqiqo ethi "ubukhulu kuqala, ukulungiswa kobunzima, kunye nesiqinisekiso esiqhelekileyo":

Okokuqala, misela uluhlu lwamandla ovavanyo ngokusekelwe kubukhulu bengubo (jonga kwitheyibhile engentla);

Lungisa ixabiso lamandla ngokwendlela obulukhuni ngayo uboya (khetha umda ophezulu wezinto ezithambileyo kunye nomda ophantsi wezinto eziqinileyo);

Okokugqibela, hambelana nemigangatho yoshishino (efana ne-ISO 14577 kunye ne-ASTM E384) ukuqinisekisa ukuba iziphumo zovavanyo ziyasebenza.

Ixesha leposi: Sep-03-2025