1) Ngaba isixhobo sokuvavanya ubulukhuni beRockwell singasetyenziselwa ukuvavanya ubulukhuni bodonga lombhobho wentsimbi?

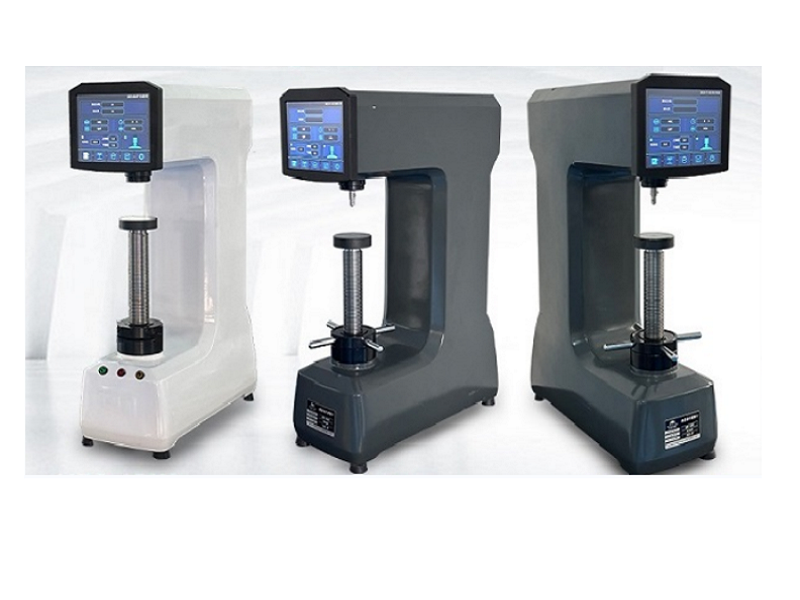

Izinto zovavanyo yipayipi yentsimbi ye-SA-213M T22 enobubanzi bangaphandle obuyi-16mm kunye nobukhulu bodonga obuyi-1.65mm. Iziphumo zovavanyo lwe-Rockwell hardness tester zezi zilandelayo: Emva kokususa i-oxide kunye nomaleko okhutshwe kwi-specimen kumphezulu we-specimen nge-grinder, i-specimen yabekwa kwitafile yokusebenza enomfanekiso we-V kwaye uvavanyo lwe-Rockwell hardness lwenziwa ngqo kumphezulu wayo wangaphandle, kusetyenziswa i-HRS-150S digital display Rockwell hardness tester kumthwalo:980.7N.

Emva kovavanyo, kubonakala ukuba umbhobho wentsimbi eludongeni unenguquko encinci, kwaye isiphumo kukuba: ixabiso eliphantsi elilinganisiweyo lobunzima beRockwell lenza uvavanyo lungasebenzi.

Ngokutsho kwe-GB/T 230.1-2018 « Uvavanyo loBulukhuni beRockwell kwizinto zesinyithi Icandelo 1: Iindlela zoVavanyo », ubulukhuni beRockwell buyi-80HRBW kwaye ubuncinci bobukhulu besampuli yi-1.5mm. Ubukhulu besampuli No.1 yi-1.65mm, ubukhulu bomaleko osuswe kwikhabhoni yi-0.15~0.20mm, kwaye ubukhulu besampuli emva kokususa umaleko osuswe kwikhabhoni yi-1.4~1.45mm, obukufutshane nobukhulu obuncinci besampuli echazwe kwi-GB/T 230.1-2018.

Ngexesha lovavanyo, ngenxa yokuba iziko lesampulu alixhaswa, kuya kubangela ukuguquguquka okuncinci (mhlawumbi okungabonakaliyo ngeliso lenyama), ngoko ke ixabiso elilinganisiweyo lobunzima beRockwell liphantsi kakhulu.

2) Indlela yokukhetha okungaphezuluuRockwellumvavanyi wobulukhuni wokuvavanya imibhobho yentsimbi:

Inkampani yethu ivavanye ngokuphindaphindiweyo ubulukhuni bomphezulu wombhobho wentsimbi kwaye ifikelele kwizigqibo ezilandelayo.:

Uvavanyo lokuqina oluphezulu lweRockwell okanye uvavanyo lokuqina lweRockwell kumphezulu wombhobho wentsimbi onodonga oluncinci. Ukungabikho kwenkxaso yodonga eyaneleyo kuya kubangela ukuguquka kwesampuli kwaye kubangele iziphumo zovavanyo eziphantsi;

Ukuba ufake inkxaso yesilinda embindini wetyhubhu yentsimbi eludongeni olubhityileyo, kuba ayinakuqinisekisa ukuba i-axis ye-indenter kunye nolwalathiso lomthwalo kunye nomphezulu wombhobho wentsimbi zithe nkqo kumphezulu, kunye nomphezulu wangaphandle wombhobho wentsimbi kwaye apho kuya kubangela umsantsa wenkxaso yesilinda yomsantsa phakathi komphezulu ojikelezayo wombhobho wentsimbi kunye nomphezulu wenkxaso yesilinda, kuya kubangela ukuba iziphumo zovavanyo zibe ziphantsi kakhulu.

Guqula uvavanyo lobunzima beVickers lube luvavanyo lobunzima beRockwell emva kokupolisha isampuli yombhobho wentsimbi, kuya kufumana ixabiso lobunzima beRockwell elichanekileyo.

2. Emva kokususa umaleko we-oxide kunye ne-decarburization kumphezulu wombhobho wentsimbi kunye nokucoca iplani yovavanyo kumphezulu ongaphandle kunye nokuyibeka ngaphakathi, ixabiso lichaneke ngakumbi xa lithelekiswa ne-Superficial Rockwell hardness tester kunye ne-Rockwell hardness tester.

Ixesha leposi: Meyi-28-2024