1) Ngaba isixhobo sokuvavanya ubulukhuni beRockwell singasetyenziselwa ukuvavanya ubulukhuni bodonga lombhobho wentsimbi?

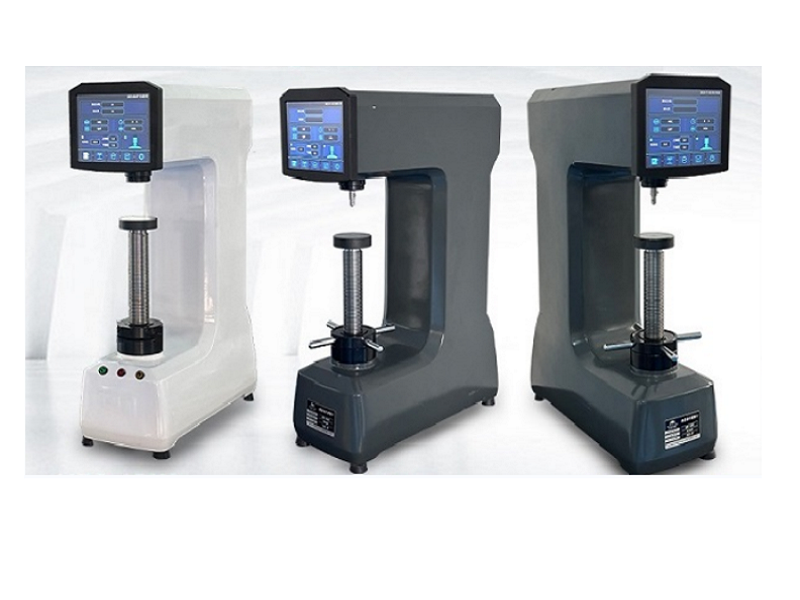

Izinto zovavanyo yipayipi yentsimbi ye-SA-213M T22 enobubanzi obungaphandle be-16mm kunye nobukhulu bodonga be-1.65mm. Iziphumo zovavanyo lovavanyo lobunzima beRockwell zezi zilandelayo: Emva kokususa isikali se-oxide kunye nomaleko wokurhoxisa phezu komphezulu wesampuli nge-grinder, isampuli ibekwa kwibhentshi yokusebenzela enomfanekiso we-V, kwaye i-HRS-150S digital Rockwell hardness tester isetyenziselwa ukuvavanya ngokuthe ngqo ubunzima beRockwell kumphezulu wayo ongaphandle ngomthwalo we-980.7N. Emva kovavanyo, kunokubonwa ukuba udonga lombhobho wentsimbi lunokuguquguquka okuncinci, kwaye isiphumo kukuba ixabiso lobunzima beRockwell elilinganisiweyo liphantsi kakhulu, nto leyo ebangela uvavanyo olungasebenziyo.

Ngokutsho kwe-GB/T 230.1-2018 «Uvavanyo loBulukhuni beZinto zeMetallic Rockwell Icandelo 1: Indlela yoVavanyo», ubulukhuni beRockwell buyi-80HRBW kwaye ubuncinci besampulu ubukhulu yi-1.5mm. Ubude besampulu No. 1 yi-1.65mm, ubukhulu bomaleko osuswe kwikhabhoni yi-0.15~0.20mm, kwaye ubukhulu besampulu emva kokususa umaleko osuswe kwikhabhoni yi-1.4~1.45mm, obukufutshane nobukhulu obuncinci besampulu obuchazwe kwi-GB/T 230.1-2018. Ngexesha lovavanyo, ekubeni kungekho nkxaso embindini wesampulu, kuya kubangela ukuguquguquka okuncinci (okunokungabonwa ngamehlo enyama), ngoko ke ixabiso lokwenyani lobunzima beRockwell liphantsi.

2) Indlela yokukhetha isixhobo sokuvavanya ubulukhuni bomphezulu kwimibhobho yentsimbi:

Emva kovavanyo oluninzi malunga nobunzima bomphezulu weepayipi zentsimbi, inkampani yethu ifikelele kwizigqibo ezilandelayo:

1. Xa kusenziwa uvavanyo lobunzima beRockwell kumphezulu okanye uvavanyo lobunzima beRockwell kumphezulu wemibhobho yentsimbi enodonga oluncinci, inkxaso enganeleyo yodonga lombhobho iya kubangela ukuguquka kwesampuli kwaye ikhokelele kwiziphumo zovavanyo eziphantsi;

2. Ukuba inkxaso esisilinda yongezwa embindini wombhobho wentsimbi onodonga oluncinci, iziphumo zovavanyo ziya kuba ziphantsi kuba i-axis yentloko yoxinzelelo kunye necala lomthwalo womthwalo azinakuqinisekiswa ukuba zithe nkqo kumphezulu wombhobho wentsimbi, kwaye kukho umsantsa phakathi komphezulu wangaphandle wombhobho wentsimbi kunye nenkxaso esisilinda efakelweyo.

3. Indlela yokuguqula ubulukhuni beVickers obulinganisiweyo bube bubunzima beRockwell emva kokufaka nokupolisha isampuli yombhobho wentsimbi ichanekile.

4. Emva kokususa isikali se-oxide kunye nomaleko wokurhoxisa i-carburization kumphezulu wombhobho wentsimbi kunye nokulungisa iplani yovavanyo kumphezulu ongaphandle kunye nokuyibeka ngaphakathi, ubunzima bomphezulu weRockwell buguqulwa bube bubunzima beRockwell, obuchanekileyo.

Ixesha lokuthumela: Juni-13-2024