Kwiimveliso zoshishino, intsimbi yegiya isetyenziswa kakhulu kwiinkqubo zokuhambisa umbane kwizixhobo ezahlukeneyo zoomatshini ngenxa yamandla ayo aphezulu, ukumelana nokuguguleka kunye nokumelana nokudinwa. Umgangatho wayo uchaphazela ngokuthe ngqo umgangatho kunye nobomi bezixhobo. Ke ngoko, ulawulo lomgangatho wentsimbi yegiya lubaluleke kakhulu. Xa ukhetha, amandla ayo, ukuqina kunye nokumelana nokuguguleka kufuneka kuqwalaselwe. Ngaphambi kokucubungula intsimbi yegiya, kufuneka sihlalutye isakhiwo se-metallographic, ubunzima, ukwakheka kweekhemikhali, njl.njl. kwezinto. Ulwakhiwo lwe-metallographic kunye nobunzima bentsimbi yegiya zizibonakaliso eziphambili zokuvavanya iimpawu zayo zoomatshini, iziphumo zonyango lobushushu kunye nobomi benkonzo. Uhlalutyo lwe-metallographic kunye novavanyo lobunzima bentsimbi yegiya kufuneka lulandele ngokungqongqo inkqubo esemgangathweni, kwaye lwenze isicwangciso sovavanyo esisekelwe kwiimpawu zezinto kunye neemeko zokusebenza:

Okokuqala, uhlalutyo lwe-metallographic. Ulwakhiwo lwe-metallographic lwentsimbi yegiya lunempembelelo enkulu ekusebenzeni kwayo, njengobunzulu bomaleko we-carburised, ubungakanani beenkozo, ukusasazwa kwe-carbide, njl. Kubalulekile ukumisela amanyathelo ohlalutyo, afana nokuvavanya, ukulungiswa kwesampuli, ukugqwala, uze emva koko ujonge isakhiwo. Kungafuneka kwakhona ukukhankanya iintlobo zezicubu eziqhelekileyo, ezifana ne-martensite, i-bainite, i-pearlite, kunye nendlela yokuvavanya ukuba ezi zicubu ziyahlangabezana nemigangatho.

Emva koko kuza uvavanyo lobunzima. Ubunzima bentsimbi yegiya bunxulumene ngokuthe ngqo nokumelana nokuguguleka kunye namandla. Iindlela zovavanyo lobunzima eziqhelekileyo ziquka ubulukhuni beRockwell, ubulukhuni beBrinell, ubulukhuni beVickers, kunye nobunzima beRockwell yomphezulu kwiileya ezifakwe i-carburing. Kubalulekile ukuchaza iimeko ezifanelekileyo zeendlela ezahlukeneyo zovavanyo, ezifana neVickers okanye iRockwell yomphezulu kwiileya ezifakwe i-carburing, kunye neBrinell okanye iRockwell kubulukhuni ngokubanzi. Kwangaxeshanye, imigangatho yovavanyo, efana ne-ASTM okanye i-GB, kunye namanyathelo okhuseleko ngexesha lovavanyo, njengokukhethwa kwamanqaku ovavanyo, unyango lomphezulu, njl.njl., kufuneka kukhankanywe.

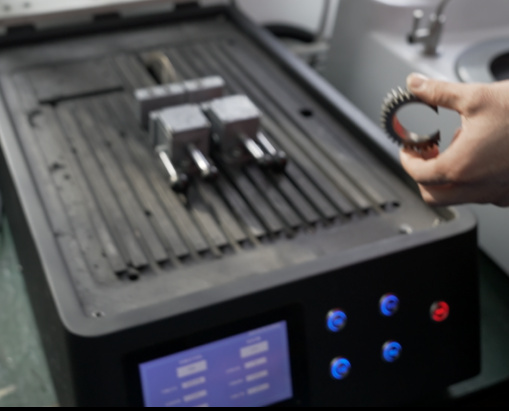

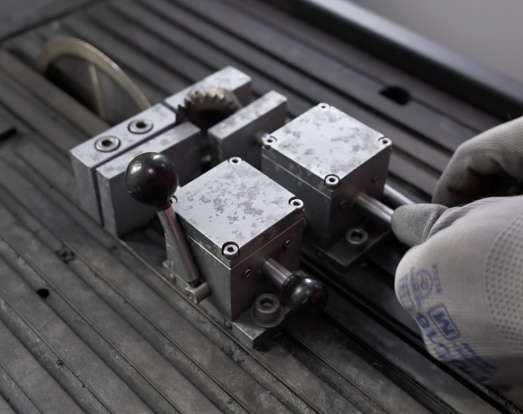

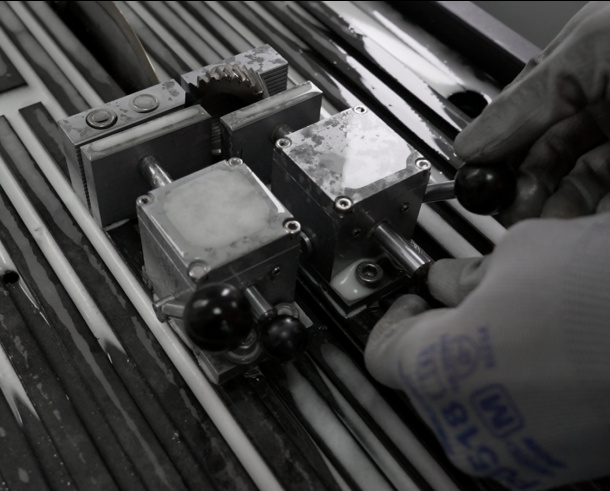

Ngaphambi kohlalutyo, kufuneka siqale sisike size sive intsimbi yegiya. Apha ngezantsi sisebenzisa umatshini wokusika isampuli ye-metallographic ngokuchanekileyo njengomzekelo ukubonisa inkqubo yokusika isampuli.

1. Khupha into yokusebenza uze uyibambe nge-quick clamp.

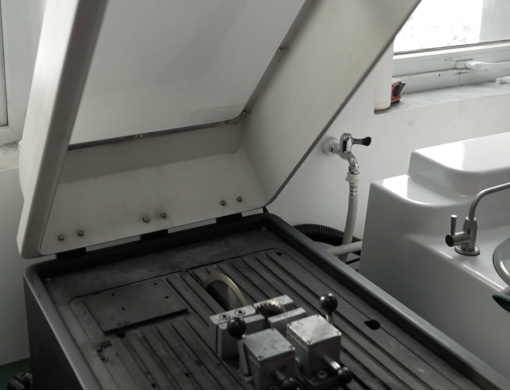

2. Emva kokubopha into yokusebenza, faka isigqubuthelo sokukhusela.

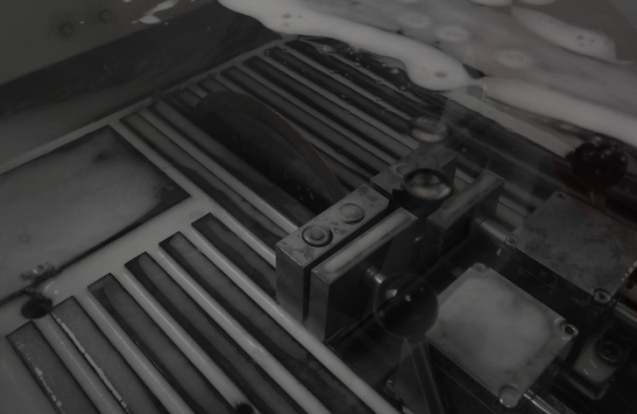

3. Beka iiparameter zokusika kwisikrini uze uqalise inkqubo yokusika

4. Vula isiciko esingaphezulu uze ukhuphe isampuli esikiweyo ukuze ugqibezele inkqubo yokusika isampuli.

Iisampulu ezisikiweyo zingasetyenziselwa iinkqubo ezilandelayo zokulungiselela iisampulu ezifana nokufakela, ukugaya, kunye nokupolisha, emva koko uvavanyo lobunzima begiya okanye uhlalutyo lwe-metallographic lunokwenziwa.

Ixesha leposi: Epreli-02-2025