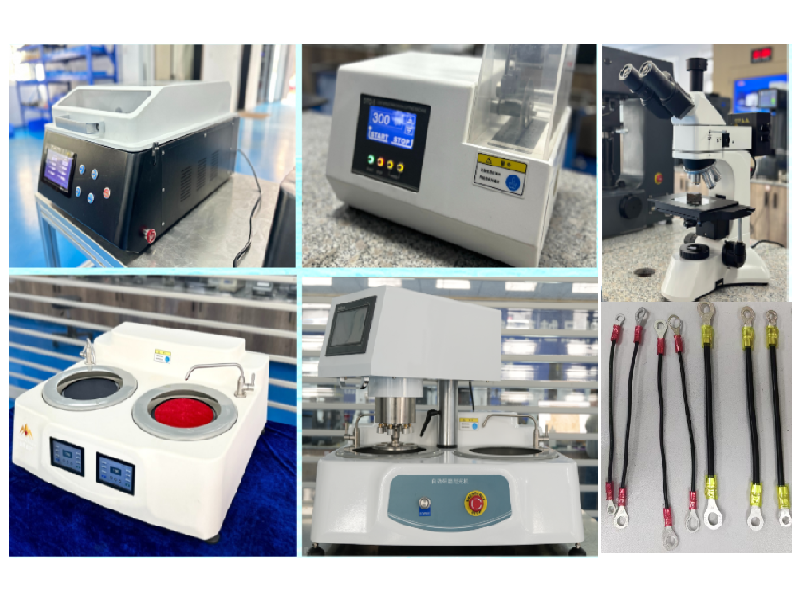

Umgangatho ufuna ukuba imilo yokugoba yesiphelo sesixhobo sokuqhagamshela ifanelekile na. Ubunzima bokugoba kwentambo yokugoba yesiphelo bubhekisa kumlinganiselo wendawo engadibananga nayo.inxalenye edibanisayo kwisiphelo se-crimping ukuya kwindawo iyonke, nto leyo eyiparameter ebalulekileyo echaphazela ukhuseleko kunye nokuthembeka kwesiphelo se-crimping. I-porosity ephezulu kakhulu iya kukhokelela ekunxibelelaneni okubi, yonyuse ukumelana nobushushu, ngaloo ndlela ichaphazela uzinzo kunye nokhuseleko loqhagamshelo lombane. Ke ngoko, izixhobo zobungcali zohlalutyo lwe-metallographic ziyafuneka ukuze kufunyanwe kwaye kuhlalutywe i-porosity yomphezulu. Ukusika isampuli ye-Metallographic, umatshini wokugaya kunye nokupolisha isampuli ye-metallographic, kunye ne-metallographic microscope ziyafuneka ukuze kuthathwe iisampulu kwaye kulungiswe isiphelo, kwaye emva koko umfanekiso wegraphic uhlalutywa yisoftware ye-metallographic microscope ukuze kuhlolwe isiphelo se-terminal.

Inkqubo yokulungiselela isampuli: Isampulu eza kuhlolwa (iimbambo zokuqinisa zesiphelo kufuneka ziphetshwe) iyasikwa kwaye ithathwe isampuli ngomatshini wokusika isampuli ye-metallographic-kucetyiswa ukuba kusetyenziswe umatshini wokusika ngokuchanekileyo ukusika, kwaye i-workpiece efunyenweyo ifakwe kwisampulu enamaqonga amabini kusetyenziswa umatshini wokufaka i-metallographic, kwaye emva koko umphezulu wokuhlola ofakwe ngaphakathi kufuneka ucolwe kwaye ucolwe kumphezulu wesibuko nge-metallographic grinder kwaye ucolwe, uze emva koko uqothulwe ngeekhemikhali kwaye ubekwe phantsi kwe-metallographic microscope ukuze uhlolwe kwaye uhlalutywe.

Ixesha leposi: Matshi-28-2025