Ikhowudi yobunzima besinyithi yi-H. Ngokweendlela ezahlukeneyo zovavanyo lobunzima, iindlela eziqhelekileyo ziquka uBrinell (HB), Rockwell (HRC), Vickers (HV), Leeb (HL), Shore (HS), njl.njl., apho i-HB kunye ne-HRC zisetyenziswa kakhulu. I-HB inoluhlu olubanzi lwezicelo, kwaye i-HRC ifanelekile kwizixhobo ezinobunzima obuphezulu, njengobunzima bonyango lobushushu. Umahluko kukuba i-indenter yomvavanyi wobunzima yahlukile. Umvavanyi wobunzima beBrinell yi-ball indenter, ngelixa umvavanyi wobunzima beRockwell yi-indenter yedayimani.

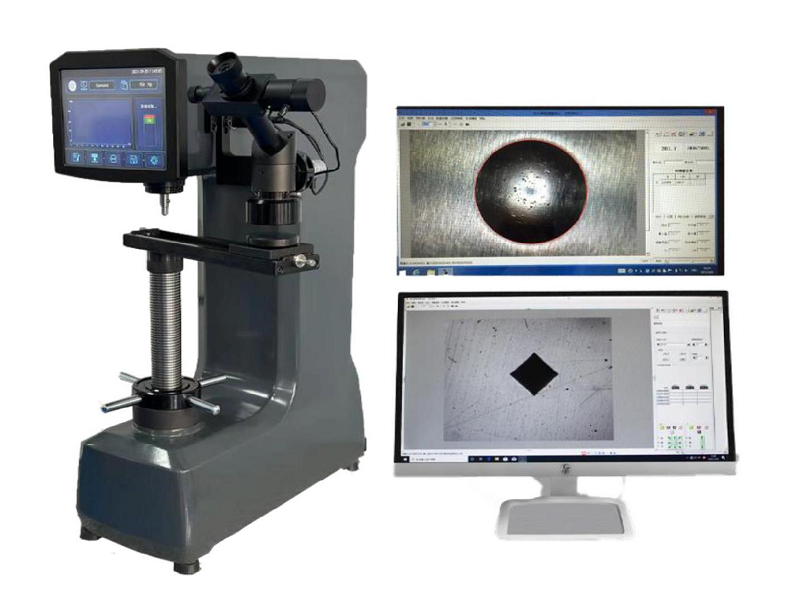

I-HV-ifanelekile kuhlalutyo lwe-microscope. Ubunzima beVickers (HV) Cinezela umphezulu wezinto ngomthwalo ongaphantsi kwe-120kg kunye ne-indenter ye-diamond square cone ene-angle ye-vertex ye-136°. Ummandla womphezulu we-indentation pit yezinto wahlulwe ngexabiso lomthwalo, eliyi-Vickers hardness value (HV). Ubunzima beVickers buchazwa njenge-HV (jonga kwi-GB/T4340-1999), kwaye bulinganisa iisampulu ezincinci kakhulu.

Isivavanyeli sobunzima esiphathwayo se-HL silungele ukulinganiswa. Sisebenzisa intloko yebhola yempembelelo ukuchaphazela umphezulu wobunzima kwaye sivelise ukugoba. Ubunzima bubalwa ngomlinganiselo wesantya sokugoba se-punch kwi-1mm ukusuka kumphezulu wesampuli ukuya kwisantya sokugoba. Ifomula yile: Ubunzima beLeeb HL=1000×VB (isantya sokugoba)/VA (isantya sokugoba).

Isivavanyeli sobulukhuni seLeeb esiphathwayo singaguqulwa sibe bubulukhuni beBrinell (HB), Rockwell (HRC), Vickers (HV), Shore (HS) emva kokulinganisa iLeeb (HL). Okanye sebenzisa umgaqo weLeeb ukulinganisa ngokuthe ngqo ixabiso lobulukhuni ngeBrinell (HB), Rockwell (HRC), Vickers (HV), Leeb (HL), Shore (HS).

Ubulukhuni be-HB - Brinell:

Ubunzima beBrinell (HB) busetyenziswa rhoqo xa izinto zithambile, njengeentsimbi ezingezizo intsimbi, intsimbi ngaphambi konyango lobushushu okanye emva kokufakelwa. Ubunzima beRockwell (HRC) busetyenziswa kakhulu kwizinto ezinobunzima obuphezulu, njengobunzima emva konyango lobushushu, njl.njl.

Ubunzima beBrinell (HB) ngumthwalo wovavanyo onobukhulu obuthile. Ibhola yentsimbi eqinileyo okanye ibhola yekhabhayithi enobubanzi obuthile icinezelwa kumphezulu wesinyithi ukuze ivavanywe. Umthwalo wovavanyo ugcinwa ixesha elithile, uze emva koko umthwalo ususwe ukuze kulinganiswe ububanzi bokuxinana kumphezulu oza kuvavanywa. Ixabiso lobunzima beBrinell yi-quotient efunyenwe ngokwahlula umthwalo ngendawo yomphezulu ongqukuva wokuxinana. Ngokubanzi, ibhola yentsimbi eqinileyo enobukhulu obuthile (ngesiqhelo yi-10mm ububanzi) icinezelwa kumphezulu wezinto eziphathekayo ngomthwalo othile (ngesiqhelo yi-3000kg) kwaye igcinwe ixesha elithile. Emva kokuba umthwalo ususiwe, umlinganiselo womthwalo kwindawo yokuxinana yixabiso lobunzima beBrinell (HB), kwaye iyunithi yi-kilogram force/mm2 (N/mm2).

Ubunzima beRockwell bumisela isalathisi sexabiso lobunzima ngokusekelwe kubunzulu bokuguqulwa kweplastiki kokutsalwa. I-0.002 mm isetyenziswa njengeyunithi yobunzima. Xa i-HB>450 okanye isampuli incinci kakhulu, uvavanyo lobunzima beBrinell alunakusetyenziswa kwaye kusetyenziswa umlinganiselo wobunzima beRockwell endaweni yoko. Isebenzisa ikhowuni yedayimani ene-engile ye-vertex ye-120° okanye ibhola yentsimbi enobubanzi be-1.59 okanye i-3.18mm ukucinezela kumphezulu wezinto ezivavanywayo phantsi komthwalo othile, kwaye ubunzima bezinto bubalwa ukusuka kubunzulu bokutsalwa. Ngokwebunzima bezinto ezivavanywayo, bubonakaliswa ngezikali ezintathu ezahlukeneyo:

I-HRA: Bubulukhuni obufumaneka ngokusebenzisa umthwalo we-60kg kunye ne-indenter ye-diamond cone, esetyenziselwa izinto ezinobunzima obuphezulu kakhulu (ezifana ne-carbide eqinisiweyo, njl.njl.).

I-HRB: Bubunzima obufumaneka ngokusebenzisa umthwalo we-100kg kunye nebhola yentsimbi eqinileyo enobubanzi obuyi-1.58mm, esetyenziselwa izinto ezinobunzima obuphantsi (ezifana nentsimbi eqhotsiweyo, isinyithi esityhidiweyo, njl.njl.).

I-HRC: Bubulukhuni obufumaneka ngokusebenzisa umthwalo oyi-150kg kunye ne-indenter yekhoni yedayimani, esetyenziselwa izinto ezinobulukhuni obuphezulu kakhulu (ezifana nentsimbi eqinileyo, njl.njl.).

Ukwengeza:

1. I-HRC ithetha isikali sobunzima beRockwell C.

2. I-HRC kunye ne-HB zisetyenziswa kakhulu kwimveliso.

3. Uluhlu olusebenzayo lwe-HRC HRC 20-67, olulingana ne-HB225-650,

Ukuba ubunzima buphezulu kunolu luhlu, sebenzisa isikali se-Rockwell hardness A HRA,

Ukuba ubunzima buphantsi kunolu luhlu, sebenzisa isikali sobunzima beRockwell B HRB,

Umda ophezulu wobunzima beBrinell yiHB650, engenakuba ngaphezulu kweli xabiso.

4. I-indenter ye-Rockwell hardness tester C scale yi-diamond cone ene-vertex angle ye-120 degrees. Umthwalo wovavanyo unexabiso elithile. Umgangatho waseTshayina yi-150 kgf. I-indenter ye-Brinell hardness tester yibhola yentsimbi eqinileyo (HBS) okanye ibhola ye-carbide (HBW). Umthwalo wovavanyo uyahluka ngokobubanzi bebhola, ukusuka kwi-3000 ukuya kwi-31.25 kgf.

5. Ukuqina kweRockwell kuncinci kakhulu, kwaye ixabiso elilinganisiweyo likwindawo ethile. Kuyimfuneko ukulinganisa amanqaku aliqela ukuze kufunyanwe ixabiso eliqhelekileyo. Ifanelekile kwiimveliso ezigqityiweyo kunye nezilayi ezincinci kwaye ihlelwa njengovavanyo olungonakalisiyo. Ukuqina kweBrinell kukhulu, ixabiso elilinganisiweyo lichanekile, ayifanelekanga kwiimveliso ezigqityiweyo kunye nezilayi ezincinci, kwaye ngokubanzi ayihlelwa njengovavanyo olungonakalisiyo.

6. Ixabiso lobunzima bobunzima beRockwell linani elingachazwanga ngaphandle kweeyunithi. (Ke ngoko, akulunganga ukubiza ubunzima beRockwell njengomlinganiselo othile.) Ixabiso lobunzima beBrinell buneeyunithi kwaye lunolwalamano oluthile oluqikelelweyo namandla okutsalwa.

7. Ubulukhuni beRockwell buboniswa ngqo kwidayali okanye buboniswe ngedijithali. Kulula ukuyisebenzisa, iyakhawuleza kwaye iyaqondakala, kwaye ifanelekile kwimveliso yobuninzi. Ubulukhuni beBrinell bufuna imakroskopu ukulinganisa ububanzi bokutsalwa, uze emva koko ujonge etafileni okanye ubale, nto leyo enzima ngakumbi ukuyisebenzisa.

8. Phantsi kweemeko ezithile, i-HB kunye ne-HRC zinokutshintshiselwana ngokujonga phezulu kwitheyibhile. Ifomula yokubala ngengqondo ingarekhodwa ngolu hlobo: 1HRC≈1/10HB.

Uvavanyo lokuqina yindlela elula nelula yokuvavanya kuvavanyo lweempawu zoomatshini. Ukuze kusetyenziswe uvavanyo lokuqina endaweni yovavanyo oluthile lweempawu zoomatshini, kufuneka ulwalamano oluchanekileyo lokuguqula phakathi kokuqina kunye namandla kwimveliso.

Uqheliso luye lwabonisa ukuba kukho ubudlelwane obuhambelanayo phakathi kwamaxabiso ahlukeneyo obulukhuni bezinto zesinyithi kunye naphakathi kwexabiso lobulukhuni kunye nexabiso lamandla. Ngenxa yokuba ixabiso lobulukhuni limiselwa kukuxhathisa kokuqala kokuguquguquka kweplastiki kunye nokuxhathisa okuqhubekayo kokuguquguquka kweplastiki, kokukhona amandla ezinto aphezulu, kokukhona ukumelana nokuguquguquka kweplastiki kuphezulu, kwaye kokukhona ixabiso lobulukhuni liphezulu.

Ixesha leposi: Agasti-16-2024