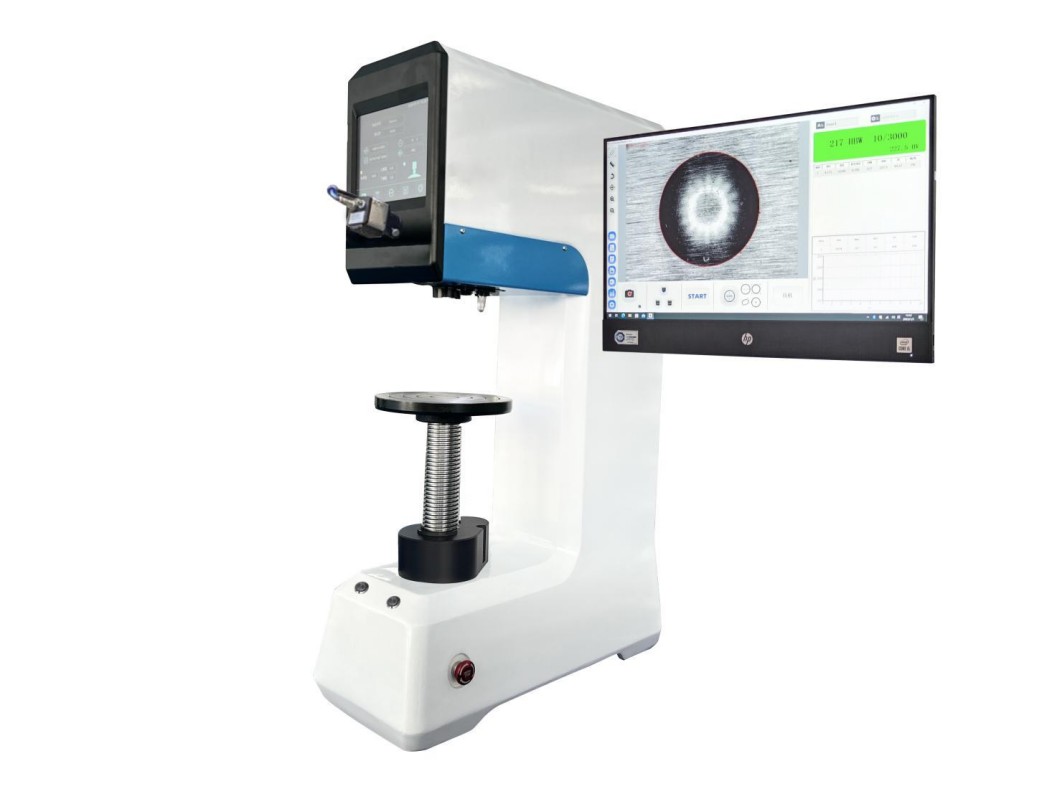

Uvavanyo lokuqina kweBrinell lwaphuhliswa yinjineli yaseSweden uJohan August Brinell ngo-1900 kwaye lwaqala ukusetyenziswa ukulinganisa ubunzima bentsimbi.

(1)HB10/3000

①Indlela yovavanyo kunye nomgaqo: Ibhola yentsimbi enobubanzi obuyi-10 mm icinezelwa kumphezulu wezinto phantsi komthwalo oyi-3000 kg, kwaye ububanzi bokutsalwa bulinganiswa ukuze kubalwe ixabiso lobunzima.

②Iintlobo zezinto ezisebenzayo: Zifanelekile kwizixhobo zesinyithi eziqinileyo ezifana nesinyithi esityhidiweyo, intsimbi eqinileyo, ii-alloys ezinzima, njl.

③Iimeko eziqhelekileyo zokusetyenziswa: Uvavanyo lwezinto ezisetyenziswa koomatshini abanzima kunye nezixhobo. Uvavanyo lokuqina kwezinto ezinkulu ezithungwayo kunye nezinto ezithungwayo. Ulawulo lomgangatho kubunjineli nakwimveliso.

④Iimpawu kunye neenzuzo: Umthwalo omkhulu: Ifanelekile kwizixhobo ezityebileyo neziqinileyo, inokumelana noxinzelelo olukhulu, kwaye iqinisekise iziphumo zokulinganisa ezichanekileyo. Ukuqina: I-indenter yebhola yentsimbi inokuqina okuphezulu kwaye ifanelekile ukusetyenziswa ixesha elide nangokuphindaphindiweyo. Uluhlu olubanzi lwezicelo: Iyakwazi ukuvavanya iintlobo ngeentlobo zezixhobo zesinyithi eziqinileyo.

⑤Amanqaku okanye imida: Ubungakanani besampulu: Kufuneka isampulu enkulu ukuqinisekisa ukuba indawo yokugquma inkulu ngokwaneleyo kwaye ichanekile, kwaye umphezulu wesampulu kufuneka ube tyaba kwaye ucoceke. Iimfuno zomphezulu: Umphezulu kufuneka ube bushelelezi kwaye ungabi nakungcola ukuqinisekisa ukuchaneka komlinganiselo. Ukugcinwa kwezixhobo: Izixhobo kufuneka zilinganiswe kwaye zigcinwe rhoqo ukuqinisekisa ukuchaneka nokuphindaphinda kovavanyo.

(2)HB5/750

① Indlela yokuvavanya kunye nomgaqo: Sebenzisa ibhola yentsimbi enobubanzi obuyi-5 mm ukuze ucinezele kumphezulu wezinto phantsi komthwalo oyi-750 kg, kwaye ulinganise ububanzi bokutsalwa ukuze ubale ixabiso lobunzima.

②Iintlobo zezinto ezisebenzayo: Zisebenza kwizixhobo zesinyithi ezinobunzima obuphakathi, ezifana nee-alloys zobhedu, ii-alloys ze-aluminium, kunye nentsimbi enobunzima obuphakathi. ③ Iimeko eziqhelekileyo zokusetyenziswa: Ulawulo lomgangatho wezixhobo zesinyithi ezinobunzima obuphakathi. Uphando nophuhliso lwezinto kunye novavanyo lwelebhu. Uvavanyo lobunzima bezinto ngexesha lokwenziwa kunye nokucutshungulwa. ④ Iimpawu kunye neenzuzo: Umthwalo ophakathi: Zisebenza kwizixhobo ezinobunzima obuphakathi kwaye zinokulinganisa ngokuchanekileyo ubunzima bazo. Ukusetyenziswa okuguquguqukayo: Zisebenza kwiintlobo ngeentlobo zezinto ezinobunzima obuphakathi ezinokuguquguquka okunamandla. Ukuphindaphinda okuphezulu: Zibonelela ngeziphumo zokulinganisa ezizinzileyo nezihambelanayo.

⑥Amanqaku okanye imida: Ukulungiswa kwesampulu: Umphezulu wesampulu kufuneka ube tyaba kwaye ucoceke ukuqinisekisa ukuchaneka kweziphumo zokulinganisa. Imida yezinto: Kwizinto ezithambileyo kakhulu okanye eziqinileyo kakhulu, ezinye iindlela ezifanelekileyo zokuvavanya ubulukhuni zinokufuneka zikhethwe. Ukugcinwa kwezixhobo: Izixhobo kufuneka zilinganiswe kwaye zigcinwe rhoqo ukuqinisekisa ukuchaneka nokuthembeka komlinganiselo.

(3)HB2.5/187.5

① Indlela yokuvavanya kunye nomgaqo: Sebenzisa ibhola yentsimbi enobubanzi obuyi-2.5 mm ukuze ucinezele kumphezulu wezinto phantsi komthwalo oyi-187.5 kg, kwaye ulinganise ububanzi bokutsalwa ukuze ubale ixabiso lobunzima.

②Iintlobo zezinto ezisebenzayo: Zisebenza kwizinto zesinyithi ezithambileyo kunye nezinye ii-alloys ezithambileyo, ezifana ne-aluminium, i-alloy ye-lead, kunye nentsimbi ethambileyo.

③Iimeko eziqhelekileyo zokusetyenziswa: Ulawulo lomgangatho wezinto zesinyithi ezithambileyo. Uvavanyo lwezinto kwimizi-mveliso ye-elektroniki kunye nombane. Uvavanyo lokuqina kwezinto ezithambileyo ngexesha lokwenziwa nokucutshungulwa.

④Iimpawu kunye neenzuzo: Umthwalo ophantsi: Isebenza kwizinto ezithambileyo ukuze kuthintelwe ukuxinana kakhulu. Ukuphinda-phinda okuphezulu: Ibonelela ngeziphumo zokulinganisa ezizinzileyo nezihambelanayo. Uluhlu olubanzi lwezicelo: Iyakwazi ukuvavanya iintlobo ngeentlobo zezinto zesinyithi ezithambileyo.

⑤ Amanqaku okanye imida: Ukulungiswa kwesampulu: Umphezulu wesampulu kufuneka ube tyaba kwaye ucoceke ukuqinisekisa ukuchaneka kweziphumo zokulinganisa. Imida yezinto: Kwizinto eziqinileyo kakhulu, kunokufuneka ukhethe ezinye iindlela ezifanelekileyo zokuvavanya ubulukhuni. Ukugcinwa kwezixhobo: Izixhobo kufuneka zilinganiswe kwaye zigcinwe rhoqo ukuqinisekisa ukuchaneka nokuthembeka kokulinganisa.

Ixesha lokuposa: Novemba-20-2024