I-LHMICV5100 I-Microscope yeMetallurgical eZimeleyo Ngokuzenzekelayo

Yonke imisebenzi yenzelwe ngokwemigaqo ye-ergonomic ukunciphisa ukudinwa ngumsebenzisi. Uyilo lwayo lwecandelo le-modular luvumela indibaniselwano eguquguqukayo yemisebenzi yenkqubo. Iquka imisebenzi eyahlukeneyo yokujonga, kubandakanya i-bright-field, i-dark-field, i-oblique illumination, i-polarized light, kunye ne-DIC differential interferometry, kunye nemisebenzi ekhethiweyo ngokusekelwe kwizicelo ezithile.

Ixhasa intsimi yokujonga ebanzi kakhulu ye-25mm ekhokelayo kwihlabathi liphela, ikuzisela amava amatsha okubukela ngokubanzi. Uluhlu olubanzi lokulungiswa kwe-diopter lunokuhlangabezana neemfuno zabasebenzisi abaninzi kwizicelo ezithile.

Iinjongo ze-semi-apochromatic ze-bright-field kunye ne-dark-field zenziwe ngeelensi ezikhethwe ngononophelo eziphezulu zokudlulisa ukukhanya kunye netekhnoloji yokugquma ephucukileyo ukuze kuphinde kuvele imibala yendalo yesampulu; uyilo lwe-semi-apochromatic lunentsebenzo egqwesileyo yokulungisa imibala, nto leyo ephucula umahluko kunye nokucaca komfanekiso ojongiweyo.

Inkqubo ye-polarization iquka i-polarizer insert kunye ne-analyzer insert, enokwenza ukufunyanwa kokukhanya kwe-polarized. Kwi-semiconductor kunye nokuhlolwa kwe-PCB, inokususa ukukhanya okulahlekileyo kwaye yenze iinkcukacha zicace ngakumbi.

I-analyzer ejikelezayo ye-360° ivumela ukubonwa ngokulula kwembonakalo yesampuli phantsi kokukhanya ngee-engile ezahlukeneyo ze-polarization ngaphandle kokuhambisa isampuli.

● Isigaba se-XY esinobunono obuphezulu, sidityaniswe nenkqubo yokulawula evaliweyo, senza ukuba umfanekiso opheleleyo uskenwe kwaye umfanekiso osebenza kakuhle uhlanganiswe, okuqinisekisa ukuhlanganiswa okungenamthungo kweendawo ezininzi zokujonga.

● Ixhasa iindlela zokuskena ezenziwe ngokwezifiso, iyaziqhelanisa neesampuli ezingaqhelekanga, kwaye iphucula izinga lempumelelo yokudibanisa iindawo ezintsonkothileyo.

●I-Z-axis inikwe amandla ngombane, nto leyo evumela ukuba umfanekiso ugxile ngokuzenzekelayo.

I-lever engaphambili kwe-illuminator yenza kube lula ukutshintsha phakathi kwamabala akhanyayo namnyama kwaye inomsebenzi wokudibanisa isihluzi esingenamda. Oku kuthintela amehlo omsebenzisi ukuba angavuselelwa kukukhanya okunamandla xa etshintsha ukusuka kumabala amnyama ukuya kumabala akhanyayo, nto leyo ephucula intuthuzelo yomsebenzisi.

I-multi-aperture objective converter ivumela ukuqwalasela okufanelekileyo nokuqhubekayo kwimilinganiselo ephantsi, ephakathi, nephezulu yesampuli efanayo kwiindawo ezahlukeneyo zokujonga.

| Inkqubo yokukhanya | Inkqubo yokukhanya elungisiweyo ngokungapheliyo |

| Ityhubhu yokujonga | Ukuthambeka okungama-30°, ityhubhu yokujonga eneendlela ezintathu engapheliyo, uhlengahlengiso lomgama phakathi kwabantwana: 50mm~76mm, umlinganiselo wokuqhekeka kwemithamo emibini, i-binocular:trino = 100:0 okanye 0:100 |

| iliso | Iliso eliphezulu, iliso elibanzi eliyiplani yeplani yeliso PL10X / 25mm, i-diopter ehlengahlengiswayo. |

| Amasimi akhanyayo namnyamaIlensi ejolise kwizinto ezintsonkothileyo | I-LMPLFL 5X /0.15 BD DIC WD13.5mmI-LMPLFL10X/0.30 BD DIC WD9.0mmI-LMPLFL20X/0.5 BD DIC WD2.5mmI-LMPLFL50X/0.80 BD WD1.0mmI-LMPLFL100X / 0.90 BD WD 1.0mm |

| isiguquli | Isiguquli esinemingxunya emi-6 seendawo ezikhanyayo nezimnyama, esine-DIC slot |

| isakhelo | Ikhamera inesakhelo sokubonisa kunye nendlela esezantsi yokujonga i-coaxial coarse kunye ne-fine focus mechanism. Uhambo lokulungisa olucothayo yi-25mm, kwaye ukuchaneka kokulungisa okucothayo yi-0.001mm. Iquka isixhobo soxinzelelo lokulungisa oluchasene nokutyibilika kunye neswitshi ephezulu engacwangciswanga. |

| Inkqubo yokukhanyisa | Isibane esikhanyayo esikhanyayo nesimnyama esine-diaphragm eguquguqukayo, i-diaphragm yentsimi, kunye nokulungiswa embindini; kunye nesixhobo sokutshintsha isibane esikhanyayo nesimnyama; kunye nesithuba sesihluzi sombala kunye nesithuba se-polarizer/analyzer. |

| igumbi lesibane | Igumbi lesibane se-halogen se-12V 100W, esifanelekileyo kokubili ukuhanjiswa kunye nokuboniswa, siyafumaneka ukuze si-odolwe kwangaphambili. |

| I-axis ka-Z | Ukugxila Okuzenzakalelayo |

| Iqonga lombane | Ukuhamba kweqonga: Icala elithe tye * Icala elithe nkqo = 80 * 60 (iyunithi: mm)I-screw lead: 2000μmUkuchaneka kokuphindaphinda kwe-XY: ngaphakathi kwe-± 2 μmUkuphindaphinda kwe-Z-axis: ngaphakathi kwe-± 1 μmIsisombululo kwiicandelo ezili-16: 0.625μm ngenyathelo ngalinye I-engile yenyathelo le-Stepper motor: 1.8° Umlinganiselo wangoku osebenzayo: 1.0A ngeshafti nganye (isebenza nge-24V) Umthwalo ophezulu: ≥5kg Ubuninzi bokuvunyelwa ukuya nokubuya: 2 micrometers Ukuphakama okuphezulu kwesampulu yi-25mm (ezinye iindebe zingenziwa ngokwezifiso). |

| Ibhokisi yokulawula iDrive | Isebenzisa i-RS232 serial port eqhelekileyo ukunxibelelana nePC (izinga le-baud eli-115200).Ulawulo lwezibuko ezijikelezayo luvumela ukuseta isantya semoto, umgama, kunye necala elihamba ngalo. |

| Ezinye izincamathiselo | Isifakelo sePolarizer, isifakelo se-analyzer esijikelezayo se-360°, kunye neseti yesihluzi sokuphazamiseka ukuze sibonakale. |

| Inkqubo yoHlalutyo | Isoftware yohlalutyo lwe-metallographic yokwenyani ye-FMIA 2025 kunye nesoftware ye-porosity |

| isixhobo sekhamera | Ii-megapixels ezi-5, ii-36 fps |

| I-interface yelensi ye-adapter ye-0.5X, i-micrometer | |

| Iikhompyutha zolawulo lwemizi-mveliso | Intel i5 iprosesa , 64GB RAM , 1TB SSD , 27-intshi 4K esweni |

Isoftware yethu yohlalutyo lwemifanekiso ye-metallographic yinkqubo entsha eyenziwe yinkampani yethu ngokusekelwe kwiimfuno zovavanyo lwe-metallographic zamashishini okusika, amashishini eenxalenye zeemoto, amashishini onyango lobushushu, amashishini esinyithi, amashishini enkqubo yamandla, amashishini eenxalenye zikaloliwe, kunye neenkampani ezahlukeneyo zovavanyo ezinxulumene noko. Ukuze siphucule izinga lokufaneleka kwemveliso kwaye sincede ekuphuculeni inqanaba lovavanyo lweelabhoratri ezahlukeneyo, siqokelele iimfuno kunye nezimvo zeengcali kunye nootitshala abavela kumashishini ahlukeneyo.

Isoftware yohlalutyo lwemifanekiso ye-metallographic iye yahlengahlengiswa ngokupheleleyo kwaye yaphuculwa. Le nkqubo igubungela inani elikhulu lemigangatho yovavanyo lwe-metallographic yasekhaya neyamazwe ngamazwe, idibanisa uhlalutyo lobungakanani nolwekhwalithi, kwaye yongeza ukuhlanganiswa kobunzulu bentsimi kunye nemisebenzi yokuthunga umfanekiso. I-interface ilula kwaye inokuqhubeka nokubamba imifanekiso yemimandla emininzi yokujonga ukuze kuhlelwe kwaye kuhlalutywe umfanekiso ophakathi. Umsebenzi ulula ngakumbi, ususa amanyathelo ahlukeneyo anzima esoftware yangaphambili, okwenza uvavanyo lukhawuleze kwaye lusebenze ngakumbi.

Siye sayila inkqubo entsha "yobuchwephesha, echanekileyo, nesebenzayo" yohlalutyo lwe-metallographic ukuze kube lula uhlalutyo lwe-metallographic.

Ilayibrari yesizwe yenkqubo yesoftware inamakhulu eendidi, ngokuyintloko igubungela imigangatho ye-metallographic esetyenziswa rhoqo kwaye ihlangabezana neemfuno zohlalutyo lwe-metallographic kunye novavanyo lwenkoliso yemibutho. Iindidi ezifanelekileyo zichaziwe kwaye zivulwa ngokweemfuno zamashishini ahlukeneyo ukuhlangabezana neemfuno zovavanyo lweshishini. Zonke iimodyuli ziyafumaneka simahla ubomi bonke, kwaye imigangatho ihlaziywa simahla ubomi bonke.

Ngenxa yokwanda kwenani lezixhobo ezintsha kunye namanqanaba angeniswayo, izixhobo kunye nemigangatho yovavanyo engakafakwa kwisoftware inokwenziwa ngokwezifiso kwaye ingeniswe ngokwahlukeneyo.

Iingenelo kunye nemisebenziyesoftware yohlalutyo lwe-metallographic:

- Ukuthathwa kwemifanekiso yevidiyo kunye nokufumana: Ukudubula iibhetshi, ukubiza amagama eebhetshi, ukugcinwa kweebhetshi, ukuprinta iibhetshi ngokukhulisa okusisigxina kunye neminye imisebenzi yokucubungula iibhetshi yemifanekiso emininzi kwenza inkqubo yokuhlola isampuli yebhetshi ibe lula kwaye isebenze kakuhle.

- Phambiliuseto lwekhamera:Ixesha lokuvezwa, ukwanda, ubukhali, ukugcwala, i-gamma, umahluko, ukukhanya, ibhalansi emhlophe, ibhalansi emnyama, kunye nezinye izicwangciso zomsebenzi.

- Cofa kube kanyeukulinganisa zonke iinjongo:Umsebenzi wokulinganisa uphuculwe ngokupheleleyo, okukuvumela ukuba ugqibezele ukulinganisa zonke iiparameter ze-objective ngokucofa kube kanye. Xa kuthelekiswa nendlela yokuqala yokulinganisa, indlela entsha yokulinganisa ilula kwaye ikhawuleza ukuyisebenzisa.

- Imisebenzi yokucubungula umfanekiso:ukwahlulwa kombala, ukuguqulwa kwe-grayscale, ukuvalwa kwemingcele, ukubekwa kwe-binarization, ukuphuculwa komfanekiso, ukuguqulwa kwesigaba, ukulola, ukususa imikrwelo kunye nokususwa kodaka, i-histogram yomfanekiso, njl.

- Isiphumo sokulinganisa umfanekiso:Iimpawu ziquka ukuprinta imifanekiso emininzi, amagama emifanekiso eyenziwe ngokwezifiso, useto lweeparameter zesikali, ukuthumela ngaphandle kwiPDF/Word/Excel, kunye nokujonga kwangaphambili kokuprinta.

Ukulinganiswa komfanekiso kunye nokugcinwa kwirekhodi:Izixhobo ezahlukeneyo zokulinganisa ziyafumaneka (kubandakanya umgama, i-engile, i-engile phakathi kwemigca emibini, uxande, umgama osuka kwindawo ukuya kumgca, i-ellipse, i-polygon, umgama ohambahambayo, i-arc enamachaphaza amathathu, isangqa esinamachaphaza amathathu, njl.njl.), okuvumela ukuzoba iintolo, ukulebhelisha umbhalo, kunye nokongeza... Kukho iindlela ezininzi ezikhoyo kwimigca encedisayo, ububanzi bomgca, kunye neeyunithi zobude; umbala wefonti yokulinganisa, ubungakanani, kunye nesitayile sefonti nazo ziyafumaneka; idatha yovavanyo ingashwankathelwa kwaye ithunyelwe kwi-Excel.

Umsebenzi wohlalutyo lombutho:Ilayibrari yesoftware inemigangatho eyahlukeneyo yovavanyo, kuquka i-GB/ASTM/ISO/DIN/QC/JB/DL/TB/SS kunye neminye imigangatho yohlalutyo lwemibutho. Imigangatho kwilayibrari yesoftware inokuphuculwa simahla, kwaye isoftware inezakhono zohlalutyo oluzenzekelayo noluthelekisayo. Inemisebenzi emithathu yokulinganisa i-metallographic: eyokuqala, eyesibini, kunye nencediswayo. Kulula, kulula, kwaye kuyakhawuleza ukuyisebenzisa, kwaye inika imilinganiselo echanekileyo nethembekileyo.

Iimpawu zokwenza ngokwezifiso eziphambili:Ulawulo lwesiteji olusebenzisa i-microscope eyenzelwe wena, ukuhlanganiswa komfanekiso, imephu yokukhanya kwe-3D, isiseko sedatha somfanekiso, njl.

Iitemplate zengxelo ezahlukeneyo:Ivelisa ngokuzenzekelayo iingxelo zohlalutyo lwe-metallographic ezinemifanekiso etyebileyo, kunye neendlela zokukhetha iingxelo ze-module enye okanye ezininzi. Iitemplate zengxelo zinokuguqulwa ukuze zibandakanye iilogo zenkampani, amagama eenkampani, iinkqubo zovavanyo, kunye nolunye ulwazi. Iitemplate zengxelo ezenziwe ngokwezifiso nazo ziyafumaneka ukuhlangabezana neemfuno zakho ezithile.

Umsebenzi wohlalutyo lwezicubu olusebenzisa i-AI:Imodyuli yohlalutyo lwezicubu ze-AI enokwenziwa ngokwezifiso isebenzisa ubukrelekrele bokwenziwa ukugqiba yonke inkqubo yohlalutyo lwesakhiwo se-microstructure kunye nokufumanisa, ichonga kwaye ihlalutye ngokuzenzekelayo isakhiwo se-microstructure sezinto. Inkqubo yokusebenza ilula, inciphisa amandla abasebenzi babasebenzi. Phucula ukusebenza kakuhle kovavanyo lwezinto.

Ithala leeNcwadi leSizwe lokuzoba eliSemgangathweni:Iqulethe amakhulu emizobo esemgangathweni kazwelonke ukuze abathengi bayifunde kwaye bayibhekisele kuyo.

Imodyuli Yokufundisa yeMetallography:Ibandakanya imodyuli yokufundisa i-metallography ukuze abathengi bayifunde kwaye bayibhekisele kuyo.

Umsebenzi woKwandisa uBunzulu beSithili se-EDF:Kwiisampulu ezingalinganiyo kwaye ezingenakulungelelaniswa kwingqwalasela, isoftware inika ubunzulu be-EDF obuguqukayo bomsebenzi wokudubula ebaleni. Ngokulungisa isondo lesandla elijolise kwi-microscope le-Z-axis micro-adjustment focusing, iinkcukacha ezicacileyo kwisampulu ziya kongezwa rhoqo kwifestile yokubonisa ye-EDF enamandla ukuze kuhlaziywe ngokuguquguqukayo. Isoftware irekhoda ngokuzenzekelayo imifanekiso ecacileyo kubunzulu obahlukeneyo bebala kwaye iyidibanise ibe ngumfanekiso ocacileyo.

Umsebenzi wokuthunga umfanekiso:Kubathengi abafuna ukuhlola indawo enkulu yokujonga, isoftware inika umsebenzi wokuthunga umfanekiso. Abasebenzisi banokuhambisa iqonga le-XY le-microscope ukuze bafumane ukuskena okupheleleyo kwemifanekiso kunye nokuhlanganiswa kwemifanekiso esebenza kakuhle ukuqinisekisa unxibelelwano olungenamthungo kwiindawo ezininzi zokujonga. Oku kuhlangabezana nesidingo somthengi sokuthatha imifanekiso yeendawo ezinkulu zokujonga isampuli kwaye kusombulula ihlazo lokungakwazi ukuthatha imifanekiso ngenxa yokungabikho komgangatho wokujonga we-microscope.

Ixhasa iindlela zokuskena ezenziwe ngokwezifiso, iyaziqhelanisa neesampuli ezingaqhelekanga, kwaye iphucula izinga lempumelelo yokudibanisa iindawo ezintsonkothileyo.

I-Z-axis inikwe amandla ngombane, nto leyo evumela ukuba umfanekiso ugxile ngokuzenzekelayo.

| GB/T 10561-2023 Ukumiselwa koMxholo oNgekho kwiMetallic | GB/T 34474.1-2017 Uvavanyo lwesakhiwo esinamabhande kwintsimbi |

| Uvavanyo lwe-GB/T 7216-2023 lweMetallographic ye-Grey Cast Iron | Umgangatho we-DL/T 773-2016 Spheroidization Rating Standard kwi-12Cr1MoV Steel esetyenziswa kwiZityalo zoMbane ezishushu |

| Uvavanyo lweMetallographic lwe-Vermicular Graphite Cast Iron lwe-GB / T 26656 - 2023 | DL / T 1422 - 2015 18Cr-8Ni Series Austenitic Stainless Steel Boiler Tube Microstructure Uvavanyo Lokuguga Oluqhelekileyo |

| Indlela yoVavanyo lwe-GB/T 13299-2022 ye-Microstructure yentsimbi | GB /T 3489-2015 Iialloy eziqinileyo - Ukuchonga i-metallographic ye-porosity kunye ne-carbon engadibaniyo |

| Uvavanyo lwe-GB/T 9441-2021 lweMetallographic ye-Ductile Iron | I-JB/T 1255-2014 Iimeko zobugcisa zoNyango lobushushu lweeNdawo zeNsimbi ezineKhabhoni ephezulu zeChromium ezithwala iibheringi eziqengqelekayo |

| Uvavanyo lwe-GB/T 38720-2020 lweMetallographic yeNtsimbi yeKhabhoni eCinyiweyo kunye neNtsimbi yoLwakhiwo lweKhabhoni ePhakathi | I-GB / T 1299 - Isixhobo kunye neNsimbi ka-2014 |

| Indlela ye-GB/T 224-2019 yokuMisela ubunzulu beLeya eValiweyo kwiNtsimbi | GB / T 25744 - 2010 Uhlolo lweMetallographic lweeNxalenye zeNtsimbi eziKhazimlisiweyo, eziCinyiweyo, neziThuthukileyo |

| Uvavanyo lweMetallographic lweNtsimbi eQhiyiweyo lweTB/T 2942.2-2018 ZG230-450 | Ukumisela kwe-GB/T13305-2008 Metallographic komxholo wendawo yesigaba se-α kwintsimbi engagqwaliyo |

| Uhlalutyo lwe-JB/T 5108-2018 lweMetallographic yeCast Brass | JB/T 9204-2008 Uhlolo lweMetallographic lweeNxalenye zeNsimbi eziQinisiweyo ze-Induction |

| Indlela ye-GB /T 6394-2017 yokuMisela ubungakanani obuqhelekileyo beenkozo zesinyithi | GB/T 13320-2007 Iintsimbi ezifakelweyo, imizobo yokulinganisa ulwakhiwo lwe-metallographic kunye neendlela zovavanyo |

| I-JB/T7946.1-2017 Metallography yee-Cast Aluminium Alloys | Umgangatho we-DL/T 999-2006 weNsimbi eSpheroidized yeZityalo zoMbane |

| JB/T7946.2-2017 Ubushushu obugqithisileyo bee-Cast Aluminium-Silicon Alloys | Izikhokelo zoBugcisa ze-DL/T 439-2006 zeZiqhoboshi zoBushushu obuPhezulu kwiZityalo zoMbane oBushushu |

| I-JB/T7946.3-2017 Cast Aluminium Alloy Pinhole | Umgangatho we-DL/T 786-2001 woVavanyo kunye nokuHlola iGraphitization yeCarbon Steel |

| I-JB/T 7946.4-2017 Metallography yee-Cast Aluminium Alloys | Idayagram ye-B/T 1979-2001 yokulinganisa iziphene zesakhiwo sesinyithi esenziwe ngolwakhiwo oluphantsi |

| GB / T 34891 - 2017 IiRolling Bearings_Iimeko zobugcisa zokunyanga ubushushu beenxalenye zentsimbi ezinekhabhoni ephezulu yeChromium | Umgangatho we-DL/T 674-1999 wePearlite Spheroidization Rating weNombolo 20 yeNtsimbi yeZityalo zoMbane oTshisayo |

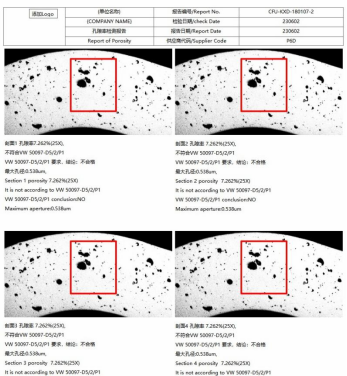

Inkqubo yohlalutyo lwemifanekiso ye-porosity ye-FKX2025 isebenzisa imifanekiso ye-microscopic ukubona i-porosity yeendawo zeemoto. Yinkqubo yokulinganisa i-porosity ye-aluminium etyhidiweyo esetyenziswa kwishishini leemoto, ehambelana nemigangatho ye-VW50097 kunye ne-PV6097 yeVolkswagen. Iziphumo zokulinganisa zichanekile kwaye zithembekile. Isetyenziselwa ikakhulu ukuhlalutya i-porosity ye-cast porosity ye-aluminium alloys kunye ne-cast iron castings, kwaye ikwafanelekile kuhlalutyo lwe-porosity kunye nohlalutyo lwe-metallographic kwezinye izinto.

Isoftware yohlalutyo lwemifanekiso ye-porosity ingasetyenziswa ngeqonga lombane ukufezekisa ukuskena ngokuzenzekelayo, ukugxila ngokuzenzekelayo, ukuthungwa komfanekiso ngokuzenzekelayo, ukulinganiswa kwe-porosity ngokuzenzekelayo, izibalo zedatha, kunye neziphumo zengxelo.

Umsebenzi wokuthunga umfanekiso:Seta iiparameter zokuthunga kunye nohlobo lomfanekiso, cofa u-"Auto Stitch," kwaye ukuthunga umfanekiso kuya kugqitywa ngokuzenzekelayo.

Useto lweeparameter zokukhangela:Ngokumisela indawo encinci, indawo ephezulu, kunye nomda, kungenziwa uphando olupheleleyo lwemephu ukuze kufunyanwe zonke iimbobo ngaphakathi kweeparamitha ezimiselweyo zemephu yonke.

Ukhetho lomfanekiso:Ibonelela ngezixhobo zokukhetha ezifana noxande, i-polygon, isangqa, isikwere, kunye nonxantathu. Emva kokuba ukhetho lugqityiwe, isoftware yenza ngokuzenzekelayo uhlalutyo lwe-porosity kwindawo ekhethiweyo.

Uhlalutyo lwemingxunya:Ingahlalutya idatha efana nomjikelezo, indawo, i-axis enkulu, i-axis encinci, ububanzi besangqa esilinganayo, umlinganiselo wobuso, kunye nokujikeleza kwembobo nganye.

Umlinganiselo wejometri:Izixhobo ezahlukeneyo zokulinganisa zingasetyenziselwa ukwenza ubungakanani

Izibalo-manani zedatha kunye nokuveliswa kweengxelo:Ingahlalutya ngokweenkcukacha idatha yeparameter eneenkcukacha kwimbobo nganye kwaye ivelise iindlela ezimbini zengxelo, i-VW50093 okanye i-VW50097.